Even miles out from an airport, the stink, noise, and sprawl attest to the heavy environmental toll that air travel imposes. Flight is carbon intensive and difficult to separate from dirty fuels. You can’t pack enough batteries into a plane to get it across even a U.S. state. And beyond CO2, other pollutants and those wispy exhaust contrails can potentially double heat trapping in the atmosphere.

That’s the bad news, but there is a surprising amount of good. Facing thin margins and fierce competition, airlines are obsessed with conserving energy. Fuel efficiency has improved about 80% since the 1950s, with at least 1.5% improvements continuing every year. There are also credible technologies—intermixed with some very optimistic predictions—to replace fossil fuels in both jet and piston engines. It will take clear thinking from engineers and judicious decisions by passengers to steer aviation toward sustainability.

Little Measures Add Up

Air travel is not the greatest transportation polluter at about 2.4% of global CO2 emissions. That would be road traffic, at about seven percent. And traveling hundreds of miles in a packed, newer airliner can be more efficient than driving in an empty SUV. “The most energy-efficient form of air transport is the highest density and least comfortable,” says Richard Aboulafia, managing director of AeroDynamic Advisory. (Packing lighter helps, too.) Although even roomy business and first class are smaller culprits than a spacious private jet, which can be from five to 14 times more polluting than an airliner.

But ingenuity—from small tweaks today to giant strides in coming decades—can slash the environmental impacts of flight, even on a Gulfstream. Flying on a newer airliner helps tremendously, with each generation boasting double-digit efficiency gains. Flying direct is less impactful because it requires fewer energy-intensive takeoffs and landings. Longer (direct) flights are easier to justify since they spread the cost of takeoff and landing over more miles. Some airlines are also more energy efficient in practices such as packing cargo, taxiing, and tweaking adjustments like wing flap angle.

These factors add up on a comparison service like Google Flights. For instance, nonstop trips from San Francisco to New York City—all lasting about five and a half hours—can vary from 21% below average CO2 emissions to 27% above. (Another option, at least for business travel, is to consider meeting online instead of in person.)

The Federal Aviation Administration’s NextGen program, launched in 2004, continues to refine logistics. New technologies allow air controllers to pack planes closer together on takeoff. And satellite navigation lets planes fly straighter routes than zigzagging to check in with ground-based beacons. “Flight planning [is] a huge part of the fuel consumption of the airplane,” says Jeff Overton, policy fellow at the Environmental and Energy Study Institute.

But there’s only so much engineers can tweak about the fundamental model of aluminum tubes propelled by burning kerosene. “When we speak about typical commercial aircraft…let’s say we are close to an efficiency limit,” says Daniel Riefer, a former Lufthansa pilot and current partner at consulting firm McKinsey.

Modern planes already incorporate a lot of lightweight materials like carbon fiber, although additional retrofits might save a bit over one percent of fuel, he says. While bigger engines can be more efficient, there isn’t much room left under the wings. And with seats already crammed in coach, ripping out first and business class is about all that remains.

Redesigns don’t address the fundamental ecological flaw: pumping carbon out of the ground into an ever-warming atmosphere. The realistic solution, say experts we spoke with, is to change where we get the carbon.”

Prospects for Radical Change

Future planes could look quite different in order to continue saving energy. NASA and Boeing are collaborating on a new design sporting extra-long, thin wings held steady by giant struts. “It’ll inform the industry decisions all the way through the 2030s in what goes into new airliners,” says Overton. Farther out are “blended wing body” designs in which the plane resembles a giant wing.

But these redesigns don’t address the fundamental ecological flaw: pumping carbon out of the ground into an ever-warming atmosphere. And technologies that replace burning carbon don’t pack nearly as much energy. The realistic solution, say experts we spoke with, is to change where we get the carbon—extracting it, not from oil wells, but from plants, garbage, even thin air.

Today’s batteries pack only about one-fortieth as much energy per pound as kerosene. Combined with hyper-efficient electric motors, they can displace gasoline for small, propeller-driven craft, such as island-hopping sea planes and urban “air taxis,” says Celina Mikolajczak. The veteran Tesla engineer led battery development for Uber’s failed air taxi venture and now heads battery tech for eco-focused materials science company Lyten. With new designs and materials, Mikolajczak is working to at least double battery capacity in five to ten years, which might be powerful enough for commuter or regional trips of a couple hundred miles.

The other carbon-free option, hydrogen, is appealing in theory: It packs about three times as much energy per pound as kerosene and leaves only water vapor in its wake. But it’s daunting in practice. Even liquified at negative 432 degrees Fahrenheit—which requires a whole new (energy intensive) fuel transport and storage infrastructure—hydrogen takes up ten times more space than kerosene. Today’s planes store fuel in the wings, but bulkier hydrogen tanks would likely have to go in the fuselage, robbing passenger and cargo space.

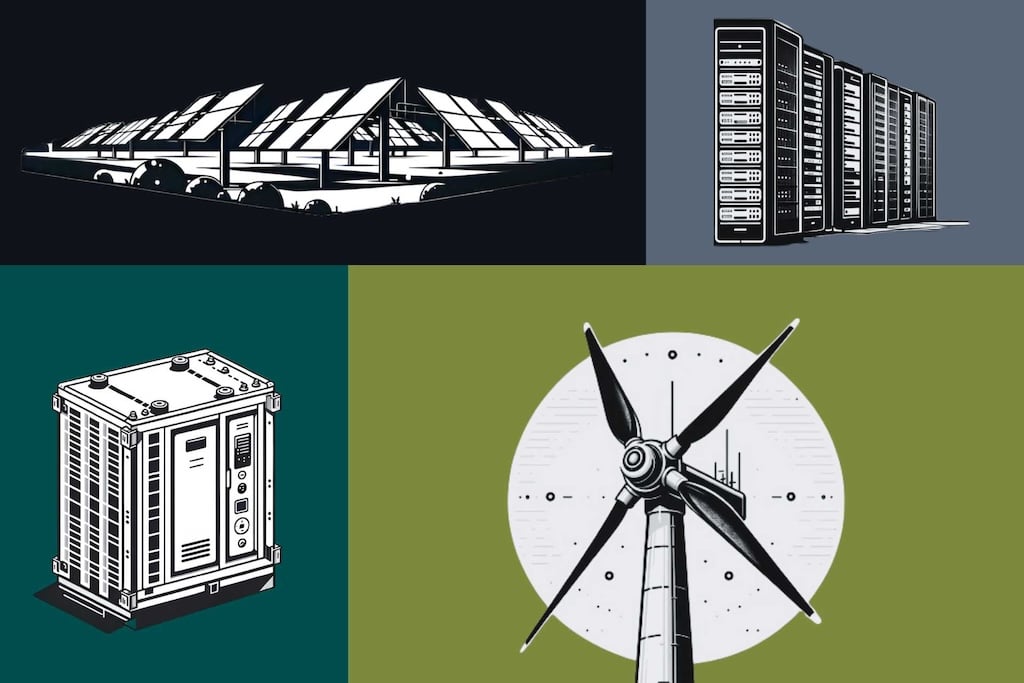

Nearly all industrial hydrogen today comes from natural gas, in a process that releases carbon. Green production requires harnessing far more renewable electricity than currently exists to instead liberate hydrogen from water molecules.

Hydrogen’s short-term bet might be in small propeller planes—using fuel cells to drive electric motors, says Carlos López de la Osa García, aviation technical manager at advocacy group Transport & Environment. Hydrogen-burning jets require entirely new designs, but Airbus promises jets capable of flying about 1000 miles by 2035. Daniel Riefer calls that “an aggressive timeline.”

Airbus believes that new plane designs and fuel tech can bring hydrogen to the biggest airliners and longest routes—eventually. “Will we see that by 2035? No,” says Amanda Simpson, a veteran pilot and VP of Research and Technology for Airbus. “Will we see that by 2050? Hmm… Will we see it by 2070? Yeah, probably.”

air taxis for short hop air travel. Photo via Wisk.

Greening Jet Fuel

Kerosene is going to continue powering most flight for the foreseeable future. Getting its benefits sustainably will require producing the fuel from carbon that’s already in the environment, rather than oil in the ground. The product, called e-kerosene or sustainable aviation fuel (SAF), is actually cleaner, producing fewer of the soot particles that water vapor crystalizes around to form heat-trapping contrails. But there’s fierce debate about what to make e-kerosene out of.

Converting farmland to grow biofuel crops like corn or palm oil could exacerbate soaring food prices and shortages. And clearing carbon-dense natural lands like forests and wetlands for fuel crops could produce up to three times more pollution than making it from petroleum. The European Union has banned aviation fuel made from food crops, and the UN’s International Civil Aviation Organization has said that it can’t be part of its plan to cut CO2 emissions to zero by 2050.

The U.S. and Brazil already make a lot of ethanol from corn, soy, and sugarcane. And growing fuel may be sustainable on some level, in some places. The Department of Energy’s Billion-Ton Report of 2016 predicted that the U.S. might sustainably grow enough crops to displace about 20% of its petroleum use.

But the study also inventoried other sources—such as agricultural and forestry residues (corn stalks, bark), manure, municipal garbage, waste cooking oil, and others—that could more than double that output. “Its determination was we do have the resources to make enough sustainable aviation fuel for our domestic industry,” says Overton. On the global scale, Riefer co-led a study with the World Economic Forum, estimating that biofuels might sustainably cover 120% of projected 2030 jet fuel demand.

“It is on the optimistic side,” says Sola Zheng, aviation researcher at the International Council on Clean Transportation. Other experts are also skeptical. And jets aren’t the only machines demanding sustainable fuel. It would be hard-to-impossible for batteries to power giant cargo or cruise ships. And electricity isn’t great for producing the intense heat that steel mills and cement factories need.

There are other ways to scrounge fuel, including the carbon dioxide and carbon monoxide spewing from those industrial facilities—which account for about one third of carbon emissions in the U.S. “Emissions from steel plants are unavoidable emissions. These are emissions that are made because of the chemistry of producing the steel,” says Johnathan Holladay, a Ph.D. chemist and VP of government programs of LanzaTech.

The company captures waste gasses and feeds them to microbes that make ethanol, which it combines with hydrogen to produce chemicals, plastics, detergents, and jet fuel. LanzaTech is capturing carbon at steel mills in China and Belgium, a refinery in India, and a trash incinerator in Japan. It’s also building a facility in Georgia slated to start making jet fuel by the end of the year. But sustainably providing the needed hydrogen, at scale, would require oodles of green power.

If all these fuel sources fall short, aviation may have to suck CO2 straight out of the air. “This is the pathway that offers the most promise to scale up because you’re taking the carbon from the entire atmosphere,” says López de la Osa García. “At the same time, it’s also more energy intensive because the carbon is more diluted.” Carbon dioxide makes up 0.04 percent of the atmosphere. Extracting it requires massive fans blowing air through systems that use chemicals and heat to separate the CO2, then passing it to compressors—all requiring renewable energy to do sustainably.

But it’s in the works. A company called Carbon Engineering, for instance, is partnering with Occidental Petroleum to build a plant in Texas designed to capture 500,000 metric tons of CO2 per year, starting in 2025. And they are planning for enough facilities to grab about 100 million tons by 2035 (about 0.28% of today’s global CO2 emissions).

A lot will be pumped underground, paid for by companies that want to offset their CO2 emissions. But a lot will go to jet fuel. “Where we can be most effective is in the hardest-to-abate industries that don’t have a lot of alternatives,” says Carbon Engineering’s VP of business development, Anna Stukas.”And aviation is almost the poster child.” Another one is direct air capture itself. Carbon Engineering will initially burn natural gas for much of the power it requires, although it will capture the CO2 produced.

A Long Trip to Sustainability

The true challenge to sustainable aviation isn’t scientific feasibility but commercial viability. The 100 million tons of CO2 that Carbon Engineering may capture in 2035 could produce about 32 million tons of jet fuel, or about 11% of current global demand. Still, that’s a massive jump from the 380,000 tons produced in 2022—about 0.1% of demand.

A sustainable future could require a mosaic of green energy sources: batteries, fuel cells, and ethanol for short hops…And a great deal of e-kerosene for long hauls.”

That small amount of fuel has a big price—from two to five times higher than fossil kerosene. The European Union may try to narrow the gap by imposing a tax on kerosene, and may mandate that airlines use ever-greater amounts of e-kerosene in their fuel mix. The U.S. Inflation Reduction Act increased tax credits for carbon capture facilities and added a credit for sustainable aviation fuel producers.

Passengers can help, too. Norwegian Airlines allows corporate customers to pay extra to subsidize e-kerosene. This is a better investment than so-called carbon offsets—funding carbon-trapping projects like tree planting or carbon capture from factories—says Sola Zheng. “It’s trying to outsource the problem, and we do need a lot of funding to pay for [sustainable fuel].”

Even luxury air travel can play a role subsidizing sustainable aviation technologies like e-kerosene and hydrogen. “The leading private jet companies in the world…are already looking into providing customers the option to decarbonize their flight,” says Riefer. “I think private aviation could take the role as a first mover and help scale sustainable aviation fuel, in a segment where customers probably have the means to pay.”

It all adds up—at least, that’s the hope. Today’s aviation’s is based on a straightforward model of converting petroleum into a kerosene for jets and gasoline for small planes. A sustainable future could require a mosaic of green energy sources: batteries, fuel cells, and ethanol for short hops; perhaps hydrogen for medium trips; and a great deal of e-kerosene for long hauls. This will require scrounging carbon from wood scraps, garbage, French fry oil, steel mills, and even thin air—combined with staggering amounts of green electricity and hydrogen to produce fuel. If all those factors come together, as quickly as possible, sustainable aviation might just work.