Harnessing mechanisms from the natural world will be a key element for reducing our carbon footprint, improving product quality, and reimagining manufacturing, two speakers at Techonomy NYC said. Both cited advances in genomics as enabling factors in this concept.

Peder Holk Nielsen, CEO of Danish company Novozymes, made the case with an activity most of us consider banal: the laundry. Thanks to the company’s engineered enzymes, which are added to laundry detergent, the same shirt that once required 140-degree Fahrenheit water to get clean can see the same result in water that’s only 80 degrees Fahrenheit. “You may not think about the difference between 80 and 140, but it’s a tremendous amount of energy,” he said. That’s just one way the company has managed to reduce carbon dioxide output by 76 million tons — the equivalent of getting 35 million cars off the road.

At Novozymes, developers don’t start from scratch for their products; the company’s model is based on tweaking enzyme activity that already exists. “Everything we do comes from nature,” Nielsen said. “It’s based on nature’s own technologies.” Other programs involve increasing crop output by figuring out which microbes help plants grow, and also boosting yield for animal husbandry and farming. Collectively, Nielsen hopes these efforts — which make heavy use of genetic data — will reduce the use of fossil fuels, though he doesn’t foresee the complete elimination of that fuel source in this century.

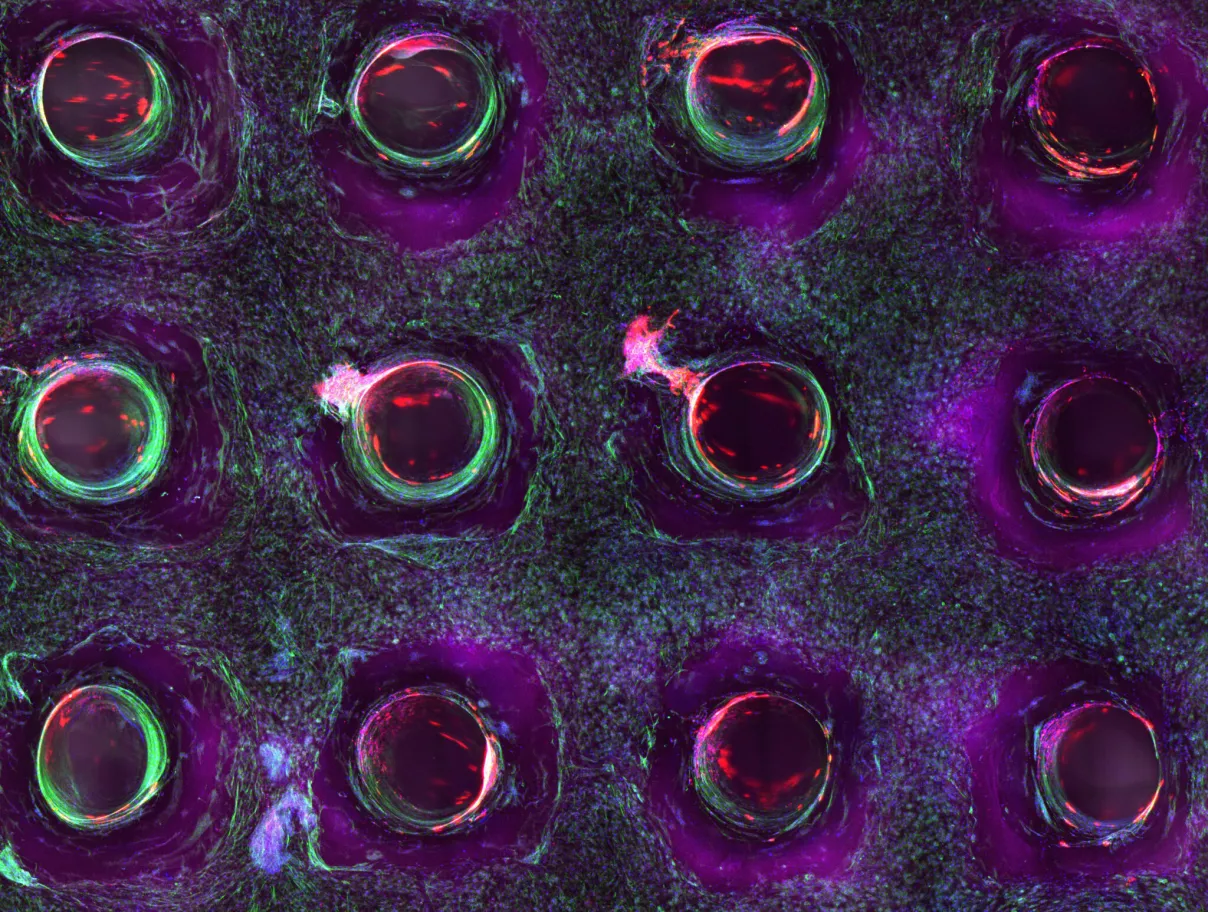

In a separate talk, John Melo, CEO of synthetic genomics firm Amyris, talked about developing entirely new production pipelines for compounds traditionally extracted from rare or tough-to-access sources. The company began with a $42.5 million grant from the Bill & Melinda Gates Foundation, allowing the team to engineer a yeast strain that produces artemisinic acid, a precursor component to an antimalarial drug. Previously, this ingredient was only available from a rare tree with highly variable yields. Since bringing this strain of yeast to market in 2013, steady availability of this drug has reduced the number of children who die from malaria each year from 1.6 million to 600,000.

After proving the engineered-yeast concept, Amyris deployed the approach for other products. Along the way, scientists dramatically improved the engineering process. Originally, it took a week to design a new strain of yeast; today, it takes just 2.5 minutes, Melo said. “We’ve created a language, we’ve created the tools, we’ve created the infrastructure, we have the data, and we do that…automatically and all the time.”

Now, the company uses yeast-based manufacturing to produce a variety of compounds: squalene, a valuable emollient used in skin creams that was previously extracted from sharks; patchouli; and vitamin E, among others. For squalene, the shift to yeast-based production is saving the lives of as many as 3 million sharks per year, Melo noted. Later this year, the company plans to launch a natural, zero-calorie sweetener.

None of these projects has the potential to solve all of the sustainability challenges we face today, but they represent a concerted push to make a difference. “It’s not going to save the world,” Nielsen said, “but it’s going to help.”

Techonomy NYC: Hacking Nature for Sustainable Development

Two speakers at Techonomy NYC look to nature for answers to separate sustainability questions.